In this post:

- Forestry Certification Schemes - an answer to the sustainability of the use of wood

- Variable components of forest certification

- International Forestry Principles

- An Example of Responsible Forest Stewardship

- Bamboo for Our Environment

- Advantages of bamboo as a building material

- Examples of bamboo structures/ buildings

- Bamboo also has certain drawbacks

- The advantages of using straw for making paper include:

- Recycled Products

Wood is part of everyday life. but current wood consumption is unsustainable and is placing tremendous pressure on the world’s remaining ancient forests. Many products presently contain wood fiber originating from ancient and endangered forests. These include paper, packaging, tape, rayon for clothing, furniture, toilet paper, and food products such as some breads and ice-creams.

The continuous manufacturing with these materials is becoming a serious issue, and there are ways we can help. For instance, there are recycling and disposal services that can help educate us on how to get rid of our trash by wasting less and recycling more.

Many of today’s products that contain old growth forest fiber, could utilize alternative fibers without negatively impacting quality or performance.

Forestry Certification Schemes – an answer to the sustainability of the use of wood

The debate surrounding forest certification has resulted in the emergence of an increasing number of standards and schemes – with the Food and Agricultural Organization (FAO) recording some 90 different initiatives worldwide. This has raised concerns that the variety of schemes on offer might confuse both consumers and producers of forest raw materials and products. Such confusion undermines the value of forest certification both as a tool to communicate good environmental practices and to promote sustainable forestry on the ground.

There needs to be a comprehensive source of comparative information on the world’s forest certification schemes designed to help overcome these problems.

One primary aim would be to provide reliable advice to customers and companies involved in the paper and wood products trade on the status of individual forest certification schemes and the labels issued under these schemes. A secondary aim would be to inform the developing international debate on harmonization and mutual recognition of the wide variety of forest certification schemes currently under development around the world.

The resource should provide a set of tools for anyone that wishes to compare the content of forest certification standards, and the procedures used to certify against these standards. Users may compare certification schemes against their own set of criteria for a credible scheme.

For representatives of forest certification schemes, the resource could provide regular updates of scheme details online. Registered schemes would benefit from the wide-ranging publicity associated with such and registered schemes may also use it to assess the strengths and weaknesses of their scheme against others.

What Is a Forest Certification Scheme?

A forest certification scheme is defined as a system of standards, rules, and procedures for assessing conformity with specified forestry requirements.

A forest certification scheme comprises at least four elements:

- Forest certification standards – documents, established by consensus and approved by a recognized body, which set out the forestry requirements which must be met.

- Forest certification – the procedure by which an independent third party gives written assurance of conformance to the forest certification standards.

- Accreditation of forest certification bodies – a procedure by which an authoritative body gives formal recognition that an independent third party is competent to carry out forest certification.

- A mechanism to control claims relating to forest management – including procedures to enforce a set of rules for organizations making these claims.

Forest certification standards-setting bodies play a more limited role and are defined as organizations that are responsible for the setting of national, regional, or provincial forest certification standards.

CEPI has identified three “key requirements” that now seem to be widely recognized as the absolute minimum necessary for credible forest certification schemes.

- ISO compatibility: during their development and subsequent operation, forest certification schemes should follow relevant ISO standards and guides.

- Legal compliance: forest certification schemes should include a requirement that forestry operations comply with all relevant international and national legislation.

- Conformance with international forestry principles: forest certification standards should address the aspects of forest management identified in one or more sets of international forestry principles.

Variable components of forest certification

While the key requirements represent a minimum threshold for credible certification, many forest certification schemes go further in establishing additional requirements for forest management to satisfy the demands of specific stakeholders. However, at this time, there is no international consensus on these additional requirements.

Furthermore, there may be good reasons for forest certification schemes to operate to variable standards and procedures.

These reasons include:

- Differences in certification scheme objectives: forest certification schemes have been developed with different aims and objectives in mind. For example, some schemes are focused mainly on providing market rewards for exemplary forest management through the labeling of forest products; others are focused more on promoting progressive improvement in forest management nationwide or industry-wide.

- Differences in the size and nature of certification applicants: for example, while some schemes require full conformance with the ISO14001 environmental management system standard, in other schemes this is not a requirement as documentary requirements of ISO14001 are regarded as too onerous for small forest enterprises.

- Differences in forest heritage: the huge variability in forest types and ownership frameworks, and the very different demands placed on forests around the world, may lead to significant and justifiable variation in the content of forest certification standards.

Therefore many components of forest certification schemes may vary depending upon the objectives and location. The website’s role with respect to these “variable components” is to report on how they are addressed, if at all, by each certification scheme. The website allows users to make their own comparisons and draw their own conclusions.

Through the provision of reliable comparative information on these components, the website aims to contribute to the ongoing international debate regarding harmonization and mutual recognition of forest certification schemes.

Some examples of “variable components” of forest certification schemes identified by CEPI include.

- Actual range of interested parties involved in the standards-setting process, and the extent of their involvement

- Scope of forest certification standards over and above the scope of international forestry principles

- Detailed content of forest certification standards

- Requirements for participation and consultation during forest management planning over and above legal requirements

- Requirements for public reports from certification applicants

- Provision of specific procedures for small forest enterprises (such as group certification, or simplified standards documents)

- Detailed requirements for forestry training and experience for auditing teams

- Detailed requirements for conformity assessment, including the use of objective evidence on the ground, sampling, interpretation of the standard, handling of non-compliances, and follow-up surveillance

- Affiliation of accreditation body to the International Accreditation Forum

- Detailed requirements for the labeling of forest products

International Forestry Principles

The content of forest certification standards is clearly critical in determining what the certification scheme delivers, both in terms of improved forestry performance and acceptance of the scheme by different stakeholders.

At an international level, a number of processes have made significant progress in identifying the range of issues that must be addressed when defining standards of “good” or “sustainable forest management.” These processes may be traced back to the discussion of sustainable development in the Brundtland report in 1987, but were greatly developed subsequently through the UNCED and related processes.

It is now widely accepted that forest certification standards should address the aspects of forest management identified in one or more of the following sets of international principles and criteria for sustainable forest management:

- Ministerial Conference on the Protection of Forests in Europe (MCPFE) Pan-European sustainable forest management criteria and indicators and operational guidelines.

- Montreal Process “Statement on Criteria and Indicators for the Conservation and Sustainable Management of Temperate and Boreal Forests” or “Santiago Declaration” (1995).

- International Tropical Timber Organization (ITTO) Guidelines for Sustainable Management of Natural Tropical Forests and Guidelines for the Sustainable Management of Planted Tropical Production Forests (1993). ITTO Criteria and Indicators of Sustainable Management of Natural Tropical Forests (1998).

- The Tarapoto Proposal (1995) under the auspices of the Amazon Cooperation Treaty (ACT), criteria and indicators for the sustainable management of Amazonian forests.

- African Timber Organization criteria and indicators for sustainable forest management in African natural tropical forests.

- National level criteria and indicators adopted by the FAO/UNEP Expert meeting on criteria and indica-CEPI Comparative Website of Forest Certification Schemes – tors for sustainable forest management in the Near East (Cairo, Egypt, 15-17 October 1996)

- The Central American Process of Lepaterique, Criteria and indicators adopted by the “Expert Meeting on Criteria & Indicators (C&I) for Sustainable Forest Management in Central America” on January 20- 24, 1997.

- The criteria and indicators agreed by a UNEP/FAO Expert Meeting on Criteria and Indicators for Sustainable Forest Management in Dry Zone Africa in Nairobi, Kenya, November 21-24, 1995. Non-Governmental· The Forest Stewardship Council (FSC) Principles and Criteria.

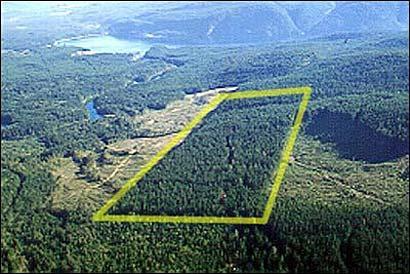

An Example of Responsible Forest Stewardship

This logging operation depicts one of the solutions being proffered. It is an eco-certified second growth woodlot in BC’s temperate rainforest. Locally controlled and operated, it provides seven times the provincial average for logging jobs per cubic meter of wood cut.

Selectively logged for the past 4 years, Al Hopwood’s woodlot is part of the solution.

The wood is available for local sawmills and furniture manufacturers as well as open log markets. The local economy is stimulated by the provision of sustainable jobs and wood supply.

Ecologically, it is a second growth forest on a gentle slope with no salmon streams. It is selectively logged and has been independently certified according to strict ecological criteria by the Silva Forest Foundation, a Forest Stewardship Council accredited certifying body. This is one of the first operations in BC to receive FSC certification. This is the future direction of forestry around the world.

Bamboo for Our Environment

Mambu, or Bamboo as it is more popularly known, is the tallest member of the grass family. It is one of the fastest growing plants on the earth, growing reportedly up to 98inches in just 24 hours. Bamboo is mainly found in Asia, some parts of Africa, and parts of Americas in many different varieties. Over centuries, bamboo has had a variety of uses like culinary, medicine, textiles, paper, construction, furniture, home décor, and musical instruments.

The use of bamboo as a construction material is not new and many countries have been using it to build homes for centuries. Generally when we think of a house made of bamboo the picture that comes to mind is a small hut in a village. But, this concept is fast changing because of the global demand for environmentally friendly and sustainable building materials. Bamboo’s unique and efficient natural design makes it a good building material.

Structure

A number of things like functionality, availability, and expenses have to be considered when choosing a building material. The natural structural design of bamboo is unique, it is hollow inside and the fibers run longitudinally hence less material mass is required when compared to timber which has a larger material mass section. When considering the load bearing mass it functions as an I-shape cross section.

Bamboo can also be shaped according to the building requirements. Bamboo that grows in a box gets a square shape and can be used for connecting items. It can be bent after freshly cut and will remain in that shape after drying too. A few species of bamboo have the same strength ratio as steel and almost twice the compression ratio of concrete. The 1999 earthquake in Colombia witnessed the destruction of all concrete buildings but houses that were built from bamboo stood still and untouched by the earthquake.

Advantages of bamboo as a building material

There are several advantages of bamboo that makes it a good building material:

- Bamboo’s strong natural fiber makes it superior to hardwood

- The versatile quality of bamboo makes it a good material for flooring, roofing, concrete reinforcement, scaffolding (used in Hong Kong for building skyscrapers), piping, and walls

- Bamboo is very flexible and hence when it grows it can be defined to grow into specific shapes. Its shock absorption capacity makes it a great building material for earthquake-resistant houses.

- Bamboo houses can also stand hurricanes with wind speeds of up to 170mph

- It is light in weight and thus transportation of bamboo is easy. Unlike other materials which require the use of cranes and heavy machinery, none is required when building with bamboo

- When bamboo is properly maintained it can last for a very long time like wood

- Bamboo is cheap and readily available in areas where it is cultivated.

- Transportation of bamboo is also cheaper than other materials

The most important quality of bamboo is its environmentally friendly quality. It is renewable and bamboo forests can be grown in a few years. Its naturally waxy surface does not require painting, making it safe from health hazards caused by paints (they contain toxic substances).

Bamboo can be smoked in its own resin making its surface impenetrable to insects thereby protecting it from insect infestation. Bamboo can be grown in a variety of climates and houses made of bamboo do not require use of other materials like concrete or steel. Pesticides and other chemicals need not be used while cultivating bamboo making it more eco-friendly.

Pollution is also reduced with bamboo cultivation as the plants reduce up to 35% carbon dioxide in the atmosphere and produce more oxygen. Studies have shown that of all the building materials that are used in construction, bamboo is the least hazardous in terms of waste as it can be recycled and does not have disposal problems. The roots in bamboo help control soil erosion as it creates a water barrier.

Developing countries use bamboo to protect their crops and villages from washing away. Bamboo consumes high quantities of nitrogen and this can help reduce water pollution. Hence, it is good to grow bamboo alongside industrial areas where it converts wastewater into nutrients for its own growth. Bamboo is also known to desalinate seawater.

Examples of bamboo structures/ buildings

Houses made of bamboo are not uncommon but what is noticeable is the use of bamboo by engineers and architects to build modern structures from bamboo.

A few examples of modern bamboo architecture are mentioned below:

- The Nato High School in the Philippines is made from bamboo and was primarily designed keeping in mind the strong tropical winds that sweep this area of the Philippines

- The Mivka hotel in Slovenia is another example of a hotel and resort that is completely made from bamboo

- The Tang Palace in Hangzhou is a restaurant with interwoven bamboo from the ceiling to the walls giving making it another example of how bamboo can be used for creating great designs

Bamboo also has certain drawbacks

- Not all types of bamboo can be used for construction

- Bamboo cannot be used to make skyscrapers that we all love

- Wet bamboo deteriorates faster

Despite all the drawbacks, the sustainable and environmentally friendly features of bamboo make it a great building material. The few drawbacks that bamboo has can be mitigated with research and the use of bamboo as an alternative building material should be encouraged to make our earth more green and pollution-free.

Agricultural Residue

Each year in North America, over 200 million tons of straw remain as a by-product of the crops of wheat, rice, rye, corn, and grass seed. This straw is generally left to compost in the fields or is burned. The burning of agricultural straw is a significant cause of air pollution and contributes to global warming.

Because of the large quantity of straw available, and their tensile qualities, many types of agricultural straw are ideal for a wide array of products including paper, building materials, textiles, and other fiber-based products.

Where storage of agricultural straw was once a limiting factor in its supply, modern harvest methods support year-round storage thus facilitating a ready and available supply of the fiber.

Although the process of pulping agri-fibers is currently more expensive than for wood-based fibers, the overall cost is lower as the price of the raw materials is significantly cheaper. The chemical processes involved with the pulping of agricultural straw are generally much more benign than with the pulping of wood fiber.

One particular application is for “agri-pulp” paper that is made from the residue straw of crops. The residue is combined with post-consumer recycled paper to make high quality papers.

The advantages of using straw for making paper include:

- A large volume of fiber is available on an annual basis.

- Straw is easy to pre-process and has greater uniformity than wood.

- Chemical pulps can be produced from straw by relatively mild treatments.

- Straw fibers are easily accessible to bleaching chemicals.

- Straw requires only low energy mechanical treatment to produce fibers.

- Straws’ thin-walled, low coarseness fibers are well suited for papermaking.

- Straw fibers have good printability and ink receptivity. The high hemicellulose and low lignin content should make straw pulps suitable for specific applications such as tissue-making or papermaking with enhanced fiber bonding.

Uses

- Paper – newsprint and office papers

- Medium-density and particle boards

- Other building materials, including insulation and countertops

- Flooring.

Chlorine-Free Products

Chlorine free products, by themselves, are not guaranteed to be free of old growth fibers. However, the bleaching process used to whiten products, particularly paper, paper products, and tissue products, is another critical environmental factor to consider when measuring the environmental credibility of a given product.

Chlorine used in manufacturing processes is damaging to the environment and to human health. As early as 1985, the U.S. Environmental Protection Agency (EPA) labeled dioxin “the most potent carcinogen ever tested in laboratory animals.”

Chlorine bonds chemically with carbon-based compounds (such as lignin in trees, the cellular material that creates the tree’s structure) to produce dioxins and toxic pollutants. When released into water, they do not break down. Dioxins, even when released in minuscule amounts, bio-accumulates as it moves up the food chain, reaching highest concentration in humans, where it is increasingly linked to cancers as well as endocrine, reproductive, nervous, and immune system damage.

There are four bleaching terms that are important to understand. Two describe processes to avoid, and two describe processes to encourage.

| Action | Acronym | Bleaching Process | Description |

| Avoid | Elemental Chlorine | A gas that brightens paper fibers and removes lignins. It binds with carbon-based compounds (such as trees) to produce dioxins and toxic pollutants. | |

| Use only if better alternatives are not available | ECF | Elemental Chlorine Free | Uses one of several chlorine compounds, most often chlorine dioxide but also sodium hypochlorite and others, that significantly reduce dioxins but do not eliminate them. Paper companies using ECF often say that dioxin is ‘nondetectable’ in their wastewater. This refers only to the sensitivity of prescribed tests, and does not necessarily mean there are no dioxins. State-of-the-art tests are often able to detect dioxins when prescribed tests find them nondetectable. |

| Prefer | TCF | Totally Chlorine Free | Uses only non-chlorine bleaching processes, including oxygen and ozone bleaching systems. Eliminates dioxins and chlorinated toxic pollutants by not producing them in the first place. |

| The Best | PCF | Processed Chlorine Free | Uses totally chlorine free processing and includes recycled content. Both the recycled fiber and any virgin fiber must be bleached without chlorine or chlorine compounds. |

Source: Susan Kinsella & Associates

Recycled Products

“Recycled” is a term that is often used loosely by companies to market their products.

Post-Consumer Recycled – a finished material that has completed its life cycle as a consumer item and would normally be disposed of as solid waste, is reconstituted into post-consumer recycled fiber in a recycling mill (e.g. office waste paper, household newspapers, and magazines). Aim for as high post-consumer recycled content as possible.

Pre-Consumer Waste Paper – paper recovered after the papermaking process, but before being used by a consumer.

Reused Product – any product, which can be used repeatedly for the same or other purposes without additional processing, except for painting, cleaning, or minor repairs.

Uses:

- Paper

- Cardboard

- Recycled plastics are suitable for furniture, pallets, structural materials, cabinetry, and flooring.

- Glass products

- Countertops and flooring materials – a combination of recycled papers and grain resins

When shopping for recycled products, clarify what percentage of the content is actually recycled, and what type of recycling is being done.

It is essential to ensure that the product in question is primarily made of recycled material. Aim for a minimum of 50% post-consumer recycled content with as high a recycled percentage as possible (e.g. 100% recycled, 60% post-consumer recycled).

The “post-consumer” part means exactly what it suggests – that it has been used out in the marketplace by the consumer and then returned to the supply machine for recycling. It has no other possible future use other than as waste.

Without this post-consumer specification, a factory could over-produce an item, have it sit on a shelf unused, and then return the item to the recycling chain without it ever having been used. Unlike the post-consumer product, this product could have many potential future uses other than as a waste product.

If the recycling process is not post-consumer, it is at odds with our goal of reducing our overall forest consumption by the reuse of forest products among other strategies.